Channel Drainage Explained

What Is Channel Drainage?

Channel drainage, also known as linear drainage, is a popular choice for many building projects because it is simple to design and straightforward to install. It consists of a long channel with grates or slots that collect surface water and direct it away from paved areas. It effectively manages run off from heavy rain, helping to create safer surfaces. Channel drains typically consist of a channel and a removable grate. You may also need sumps, end caps and other accessories to complete the installation of a linear drain.

Linear drainage is also a cheaper option for surface water drainage than a typical point water drainage system, and aesthetically, can be discreet or a design statement. Its versatility means you can efficiently manage rainfall accumulation without a major disruption to your property.

What is the Purpose of Channel Drainage?

The purpose of channel drainage is to reduce and, in some cases, even eliminate ponding and deal with heavy run-off from flash flooding and heavy downpours. Linear drainage provides a more discreet way to cover areas, as the drain channels can be longer and are efficient in controlling water flow, thereby reducing the pressure on the drainage system.

The Components of a Channel Drainage System

A typical channel drainage system is made of a few core components, each playing a crucial role in ensuring effective water management.

The main body of the channel is a long, narrow unit that forms the basis of the system. This is beneficial because it allows installers to create a continuous drainage line that matches the exact layout of the site.

A grating covers the channel; this is essential for both safety and function. The grate allows surface water to pass into the channel while preventing it from becoming a trip hazard and keeping larger debris, such as leaves and litter, from entering and causing blockages.

To seal the system and connect it to your drainage outlet, you’ll usually need end caps and outlet fittings. End caps close off any open ends of the drainage run, while the outlet allows the water collected in the channel to flow into an underground drain.

If your project involves bends or multiple branches, additional fittings such as junctions and angle connectors are available to help the system follow your layout, allowing for a seamless and integrated design across the entire surface.

Channel Drainage Benefits

Channel drainage provides numerous benefits to enhance surface conditions and keep your driveway and patio area safe and dry.

Easy to Design

When installing channel drainage, there’s no need for complicated layouts or couplers. This simplifies the process and makes it easier to avoid conflicts with underground service pipes and cables. A channel drainage system serves a dual purpose, acting as both a multipoint drain and a carrier pipe.

Straightforward Access

Grates are easy to remove with keys, bolts or locking systems. This provides you with full access to the channel below. Sumps (if needed) have easy to remove buckets, and slot drains have access units that can be opened with lifting keys.

Low Maintenance

Channel drainage systems require minimal maintenance. To ensure proper drainage, regularly clear any leaves or debris from the grating. Then, manually remove any large debris and silt from the channel and sump. Finally, use a hose to spray down the area for a thorough clean.

Visual Appeal

Channel drainage systems are versatile. Multiple removable grate designs mean that linear drainage can become a feature of the building project. Grate designs can range from floral and geometric patterns through to modern minimalistic styles, and of course standard grate designs.

Additional Benefits

- Prevents flooding — channel drainage creates a safer patio and driveway by transporting standing water away from the surface

- Enhances safety — keeps outdoor areas safer by helping to reduce slips and falls

- Protects property — floods can cause severe damage to a property, but channel drainage helps collect surface water and prevent harmful accumulation

- Erosion control — stops water from washing away soil and paving, preserving landscapes and driveways

- Cost-effective — an affordable way to manage rainfall and property drainage

What are the Different Types of Channel Drains?

Polypropylene (Plastic)

Polypropylene channel drains offer a reliable solution for managing surface water in low-impact areas. They are lightweight, easy to install and simple to maintain, while still providing enough strength for light foot traffic and domestic vehicles. Their corrosion resistance and durability make them a practical choice for residential and small commercial applications.

Concrete

Concrete channel drainage is designed to handle medium and high loads, making it ideal for areas with frequent vehicle movement. Its strength and long service life make it suitable for motorways, service stations and other high traffic locations where reliable drainage performance is essential.

Polymer Concrete

Polymer concrete channel drains are strong, lightweight and highly resistant to chemicals, making them ideal for commercial and industrial environments. They offer higher strength and lower water absorption than traditional concrete. While standard concrete relies on cement binders, polymer concrete uses resin, which provides enhanced durability in harsh conditions.

Metal

Metal channel drains offer robust and hygienic drainage, making them a reliable choice for wet rooms, showers, commercial kitchens and other moisture-prone environments. Their smooth surfaces are easy to clean, and their high strength ensures dependable performance.

Types of Grating

One of the many benefits of channel drainage is that it’s available in different styles and grating types to best accommodate your property.

Grating Materials

- Polypropylene (plastic) - light and easy to handle

- Ductile iron - preferred for heavy-duty applications

- Cast iron - exceptional strength and resistance to wear

- Stainless steel - excellent strength, ideal for light commercial areas

- Stainless ductile - strongest, most robust option

- Galvanised steel - material protects from rust and corrosion

- Aluminium - ideal for modern landscaping area

- Concrete/stone - durable and well suited to heavy-duty environments

Grating Options

- Heel guard — to prevent shoe heels from becoming stuck in the grate

- Perforated — allows for water to be collected and transported while preventing surface hazards

- Slotted — promotes effective drainage while maintaining safe surface access

- Decorative — matches your property aesthetic and enhances drainage

- Solid — used where no surface openings are required and ideal for directing water through enclosed drainage routes

- Permeable — reduces water from ponding by allowing water to pass through and disperse into the drainage system below

How to Choose Channel Drainage?

Three key things will determine the type of channel drainage you need:

- Capacity — how much water does your channel drain system need to cope with?

- Loading — how much weight will be placed on your channel drains?

- Aesthetics — what do you want your channel drainage to look like?

Channel Depth

Choose the depth of channel you require for the expected flow of drainage water. Depths range from 50mm (34cm² hydraulic section) to 650mm (1,380cm² hydraulic section).

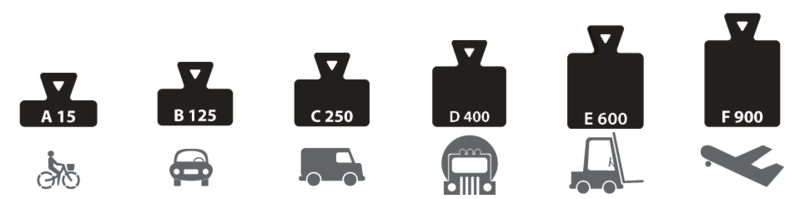

Load Class Rating

- A15 - made from lightweight materials, designed for light pedestrian areas, gardens and light use up to 1.5 tonnes

- B125 - designed for car parks, driveways and areas with light vehicle traffic up to 12.5 tonnes

- C250 - built to withstand constant pressure, used around kerbs and road edges where moderate traffic loads up to 25 tonnes are expected

- D400 - ideal for roads, motorways and heavy traffic zones supporting loads up to 40 tonnes

- E600 - suited to industrial sites, docks and service yards handling very heavy loads up to 60 tonnes

- F900 - built for extreme load environments such as airports, freight terminals and military sites up to 90 tonnes

Appearance

The appearance of your channel drainage and grating will depend on the demands of the installation. In light pedestrian areas, you can usually choose a style that suits your preferred aesthetic. In higher load environments, visual options are more limited since the focus shifts toward strength, durability and compliance.

Channel Drainage Brands

At Drainfast, we offer a wide range of channel drainage brands from high quality manufacturers.

ULMA

ULMA provides a superior system that suits any aspect of your channel drainage needs. With a vast range of sizes and load classes, Drainfast is proud to be a major UK stockist of the complete ULMA catalogue.

ULMA Benefits

- Vast range of polymer concrete channel drains; the best range of EN-1433 certified channel drain on the market

- Best of class Superior Locking System available on most ranges

- Near zero water absorption and super-fast flow rate

- Chemical resistant and unaffected by freezing/thawing cycles

- Excellent pricing and technical backup

- Huge stockholding in strategic depots available for super-quick delivery

- Rely on Drainfast’s excellent customer service to help your project run smoothly.

ACO

- ACO products are designed for discreet and efficient drainage

- Suitable for areas of light traffic to an A15 load class

- Products made from corrosion resistant materials

- Product line includes channel sections, sump units, corner units and accessories

- Designed for easy cleaning and maintenance

Explore Drainfast’s Channel Drainage Solutions

At Drainfast, we have a wide variety of channel drainage solutions for every environment. Explore our selection of durable and versatile drainage products and find the one that best suits your needs.